HIGH MACHINE PRODUCTIVITY IS ENSURED BY THE MAXIMUM NUMBER OF TECHNOLOGIES

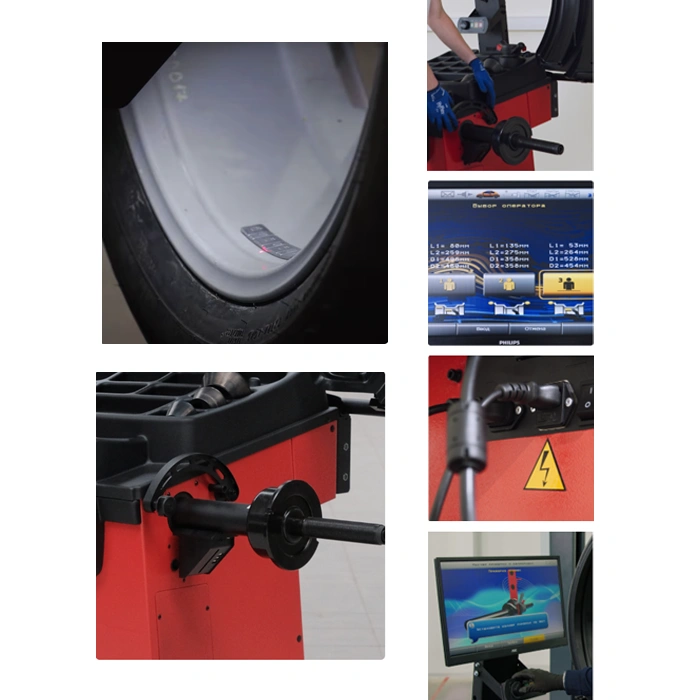

- The Direct3D function for direct measurement of weight installation planes takes into account the actual shape of the cast disk and calculates the weight accurately. To enter the size, move the ruler to the weight installation location.

- Thanks to AutoAlu technology, the machine automatically determines the load installation pattern depending on the entered wheel parameters.

- The machine automatically turns the wheel to the place where the load is installed and holds it thanks to S-Drive technology.

- Wheel balancing without pressing buttons. NoTouch technology saves time when balancing each wheel.

- LED illumination of the cleaning and load installation area speeds up the balancing process.

- The weight can be set at 12 o’clock, 6 o’clock, or using an electronic ruler.

- The laser pointer shows the weight installation point at 6 o’clock. Very convenient when balancing alloy wheels.

- An additional pedal controls the rotation of the shaft for easy tightening and removal of the quick-release nut. This is very important for high-quality wheel centering on the shaft.

- Reduces the load on the master. Increases productivity during the season.

HIGH QUALITY BALANCING (HIGH-QUALITY WHEEL CENTERING)

- The high-precision spindle unit ensures high-quality balancing. Critical parts are manufactured with an accuracy of ±0.007 mm.

- The shaft, with a diameter of 40 mm, allows the use of accessories from European manufacturers.

THE BEST ERGONOMICS IN THE BENIER BALANCING MACHINE RANGE

- The machine shaft is shifted as much as possible towards the operator. The large shaft overhang of 284 mm has been preserved. It is convenient to service even the largest and widest wheels.

- The design of the casing allows the machine to be placed close to the wall.

- The work surface area is increased by 30% compared to the previous model for convenient storage of weights, cones, quick release nuts and other tools. Deep cells accommodate a standard package of weights in one piece. There is a round cell for a bottle of degreaser.

UP TO 3 OPERATORS CAN WORK ON THE MACHINE SIMULTANEOUSLY

- It is possible to service 3 sets of wheels at the same time.

- The parameters of each set only need to be entered once.

- You can switch between sets with the press of a single button.

THE MACHINE IS RELIABLY PROTECTED FROM VOLTAGE SURGE

- Equipped with PowerGuard technology, which protects the machine’s electronics from damage during power surges.

THE CHECKING AND CALIBRATION MASTER WILL TELL YOU ABOUT THE NEED FOR CALIBRATION AND WILL HELP YOU PERFORM THEM YOURSELF

- A special “Check Wizard” will determine the need for machine calibration.

- The user can perform all calibrations independently (shaft, rulers and imbalance sensors).

Step-by-step calibration instructions with pictures and detailed descriptions.